At Pumpworks, we are committed to providing exceptional service, innovative solutions, and reliable support to our clients across Sub-Saharan Africa. Whether it’s a routine maintenance check, a complex repair, or a large-scale industrial project, we are here to ensure your equipment operates at its best, every time.

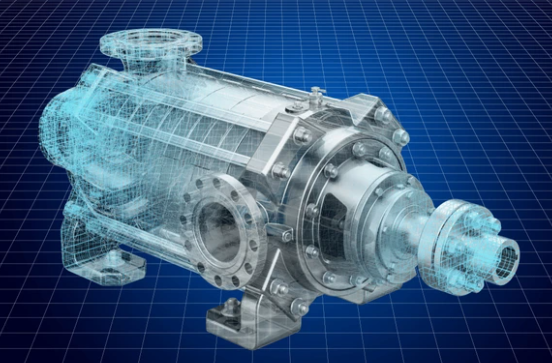

Pumpworks(Pty) Ltd is a leading South African company specializing in the repair, refurbishment, field services, supply of spares, and retrofitting of pumps, fans, and compressors.

With over 25 years of combined business experience in the OEM (Original Equipment Manufacturer) repair industry, we have established ourselves as a trusted partner for industrial equipment maintenance and optimization across Sub-Saharan Africa.

Our expertise spans a wide range of rotating equipment, including centrifugal pumps, fans, compressors, and vacuum pumps, serving industries such as mining, manufacturing, energy, food & beverage and water treatment.

Pumpworks provides high-performance rotating equipment essential for a wide range of industrial processes, within Water and Industrial Sectors

Pumpworks specializes in the repair and refurbishment of a wide range of rotating equipment, restoring them to peak performance and extending their service life.

Our field services team provides on-site support to ensure the smooth operation and maintenance of industrial equipment.

What is Rotational Bending Fatigue?

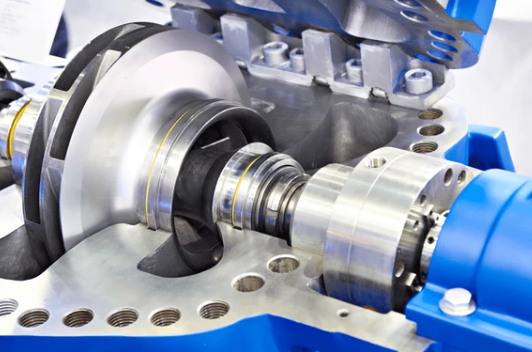

Rotational bending fatigue occurs when a pump shaft is subjected to repeated cyclic stresses as it rotates. These stresses arise from imbalances, misalignments, or uneven loading, causing the shaft to bend slightly with each rotation. Over time, this cyclic bending leads to the development of microscopic cracks, which can propagate and eventually result in shaft failure.

In centrifugal pumps, the shaft is constantly under stress due to the combination of rotational forces, hydraulic loads, and mechanical loads from connected components like impellers and couplings. When these stresses exceed the material's endurance limit, fatigue failure becomes inevitable.

Causes of Rotational Bending Fatigue

Several factors can contribute to rotational bending fatigue in centrifugal pumps:

Why Balancing Matters

Balancing is the process of aligning the mass distribution of a rotating component, such as an impeller or rotor, with its axis of rotation.

When a fan or compressor is unbalanced, it can lead to excessive vibrations, increased wear and tear, and even catastrophic failures. Here’s why balancing is so important:

International Balancing Standards

To ensure consistency and reliability, balancing is governed by international standards. The most widely recognized standards are set by the International Organization for Standardization (ISO), particularly ISO 1940-1 for balancing rotating machinery. These standards provide guidelines for acceptable levels of residual unbalance based on the machine’s size, speed, and application.